Central Chiller Plant EngineeringTechnical Services

Specialized Maintenance for Screw, Scroll & Centrifugal Chillers in Dubai. We handle Cooling Towers, Compressors, and Plant Room Hydraulics.

- 1. Air Cooled Chillers

- 2. Water Cooled Plants

- 3. Cooling Towers

- 4. Compressor Overhaul

- 5. Annual Maintenance Contracts

Major Chiller Overhauls

Recent heavy engineering projects: Compressor swaps, Tube descaling, and Plant room refurbishment.

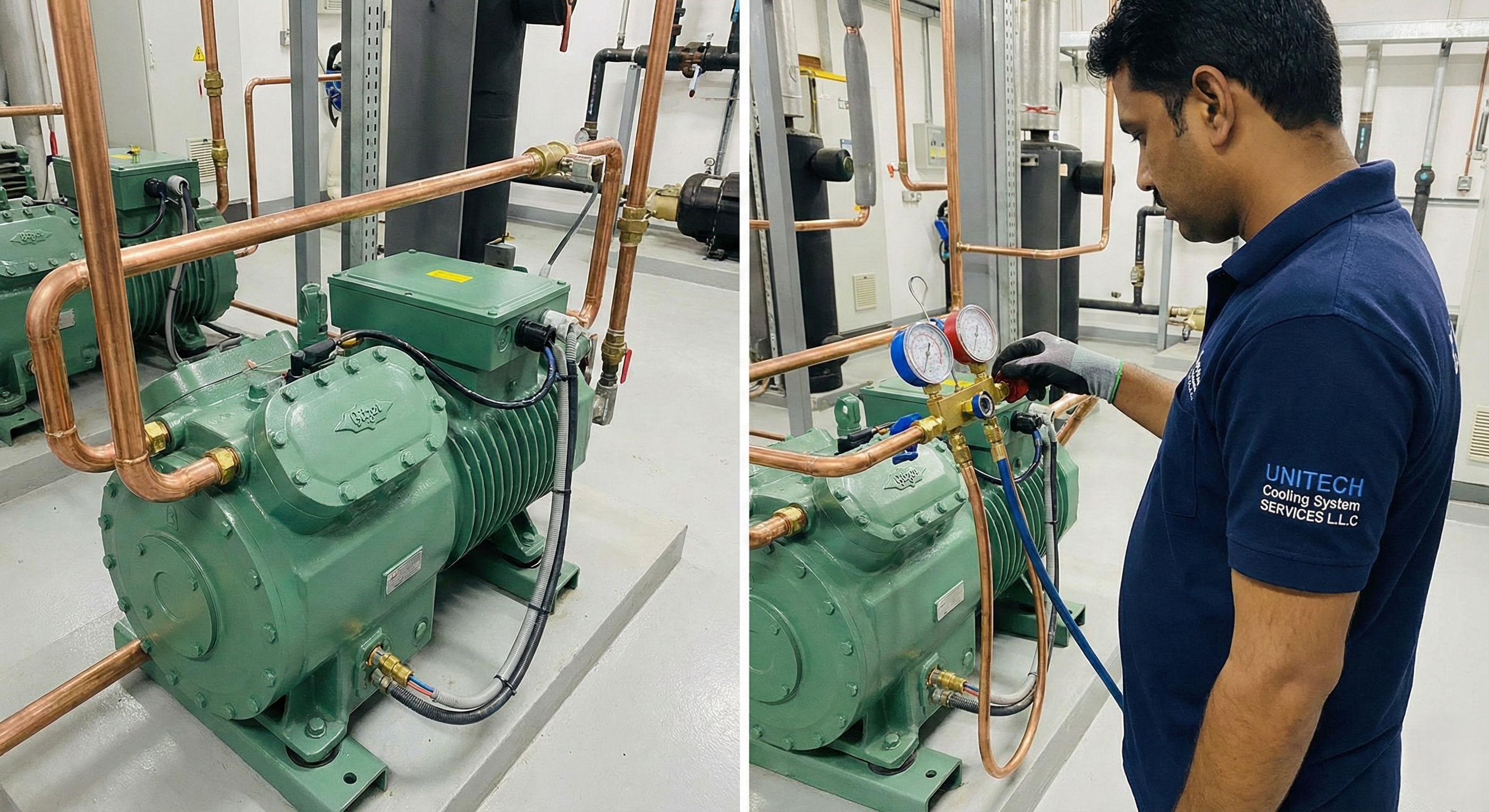

Screw Compressor Replacement

Diagnosis & Solution

Factory chiller failed due to compressor winding burnout. Decommissioned old unit, lifted new Bitzer screw compressor via crane, and commissioned with fresh oil.

Cooling Tower Refurbishment

Diagnosis & Solution

Cooling tower approach temperature was high. Replaced collapsed fill packs, aligned the fan belt, and coated the basin to prevent leaks.

Condenser Tube Descaling

Diagnosis & Solution

Water Cooled Chiller tripping on high pressure. Opened the marine water box and performed rotary brush cleaning to remove heavy calcium scaling.

Refrigerant Gas Leak Repair

Diagnosis & Solution

Carrier Air Cooled Chiller lost all R134a charge. Traced leak to condenser bend, brazed, pressure tested with Nitrogen, and recharged 120kg of gas.

Chilled Water Pump Seal

Diagnosis & Solution

Primary chilled water pump was flooding the plant room. Isolated the pump, replaced the mechanical seal and bearings, and laser aligned the coupling.

Live Telemetry & Logistics

Real-time coordination of our 17 specialist teams across Dubai.

Central Chiller Engineering & Hydraulics

We provide advanced engineering solutions for Air Cooled and Water Cooled Plants. Our technicians are experts in Screw/Scroll Compressors and Cooling Tower refurbishment.

11. Air Cooled Chiller (Rooftop)

The primary cooling engine for shopping malls and commercial buildings.

Technical Information

Located on rooftops. Vulnerable to Dubai's ambient heat. Contains Compressors (Screw/Scroll) and Condenser Coils.

Working Principle

Refrigerant gas is compressed, passes through condenser coils where fans reject heat to the atmosphere, then expands to cool the chilled water loop.

Service Protocols & Engineering Solutions

Heat Rejection Service

- High-pressure chemical coil washing

- Condenser fan motor replacement

- Fin combing & straightening

Critical Repair

- High Pressure Trip diagnostics

- Compressor contactor replacement

- Filter Drier core replacement

22. Water Cooled Chiller (Plant)

Heavy-duty efficiency for high-rise towers and industrial plants.

Technical Information

Located in basement plant rooms. Uses a 'Shell & Tube' condenser cooled by water from a Cooling Tower. Lower operating pressures.

Working Principle

Refrigerant heat is transferred to water in a shell-and-tube condenser. This warm water is pumped to a cooling tower for evaporation.

Service Protocols & Engineering Solutions

Tube Maintenance

- Condenser tube brushing (Descaling)

- Eddy Current Testing

- Marine water box gasket replacement

Oil System

- Compressor overhaul

- Oil acidity analysis

- Oil heater element testing

33. Cooling Towers

Critical heat rejection units for Water Cooled Chillers.

Technical Information

Evaporative cooling devices that release heat from the condenser water. Prone to scaling, algae, and legionella.

Working Principle

Warm water drips through fill packs while large fans pull air upwards, evaporating a small portion to cool the rest.

Service Protocols & Engineering Solutions

Basin & Fill

- Fill pack descaling & cleaning

- Float valve adjustment

- Basin sludge removal

Mechanical

- Gearbox oil change

- Drive shaft alignment

- Fan belt & motor alignment

44. Compressor & Refrigeration

The heart of the chiller system (Screw, Scroll, Centrifugal).

Technical Information

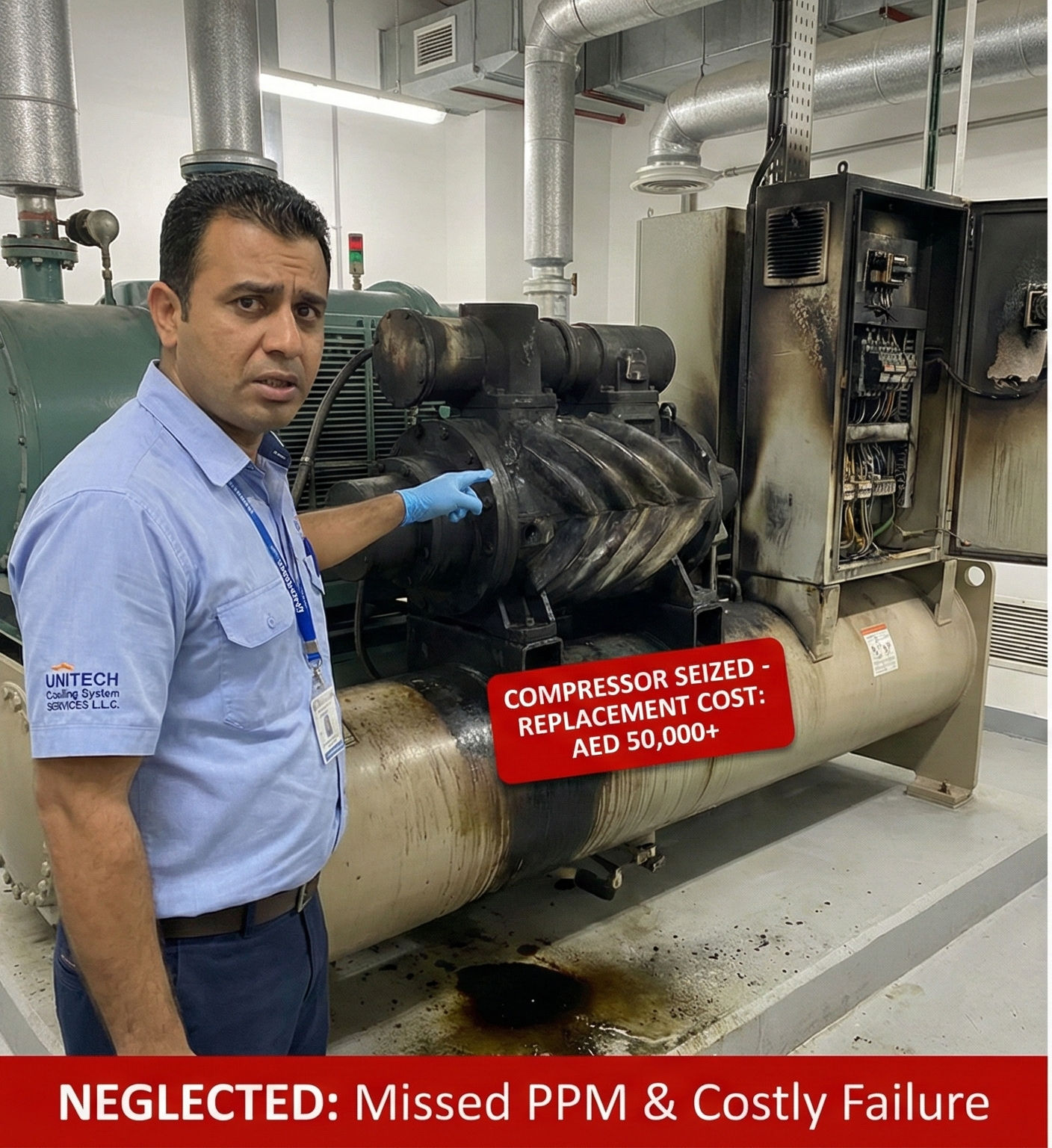

Compressors are the most expensive component. Issues include Burnout, Liquid Slugging, and Oil Failure.

Working Principle

Compresses low-pressure refrigerant vapor into high-pressure gas. Requires precise lubrication and superheat settings.

Service Protocols & Engineering Solutions

Gas & Leaks

- Nitrogen pressure testing

- Leak brazing & repair

- Gas repair & recharging (R134a)

Diagnostics

- Oil acidity testing

- Vibration analysis

- Motor winding insulation test (Megger)

55. Chilled Water Pumps & AHU

Distribution network delivering cold energy to the building.

Technical Information

Includes Primary and Secondary pumps. Circulates 44°F water to Air Handling Units (AHUs) throughout the facility.

Working Principle

Centrifugal pumps push water to AHUs. AHUs blow air over cold coils to cool the space.

Service Protocols & Engineering Solutions

Hydraulics

- Mechanical seal replacement

- Pump alignment

- Strainer basket cleaning

Air Side

- AHU belt & bearing service

- Motor bearing lubrication

- 3-Way valve actuator check

Efficiency & Uptime Strategy

Dirty coils and scaling cause High Pressure Trips. Our 60% focus is on Heat Rejection Maintenance (Coil Washing & Descaling).

Condenser Coil Chemical Foam Wash

Dust on rooftop coils causes High Pressure Trips. We use specialized alkaline foam to degrease coils and restore heat transfer.

Cooling Tower Descaling

Mineral scale blocks water flow in cooling towers. We perform chemical descaling and fill pack cleaning to prevent fouling.

Predictive Maintenance (PPM)

Prevent expensive failures. We provide daily logs, vibration analysis, and oil testing to catch issues before they crash the plant.

Industrial Pricing

Transparent B2B Rates. VAT Included. Official Invoices.

Call-Out & Inspection

- Troubleshooting Trip

- Gas pressure check

- Electrical amp check

- Detailed Technical Report

Gas Leak Repair

- Nitrogen Pressure Test

- Brazing Works

- Vacuum Pulling

- Refrigerant Gas (Per KG)

Compressor Replacement

- New Screw/Scroll Compressor

- Oil Charge

- Crane/Lifting

- Commissioning

Case Studies

Critical infrastructure repairs across Dubai.

BEFORE

BEFORE AFTER

AFTERShopping Mall Rooftop - Air Cooled Chiller

Problem: High Pressure Trip during peak summer (48°C). System shutdown affecting mall cooling.

Solution: Deep chemical foam cleaning of choked condenser coils and fan motor replacement.

Result: Head pressure normalized. Cooling restored in 4 hours.

BEFORE

BEFORE AFTER

AFTERHigh-Rise Tower - Water Cooled Chiller

Problem: Compressor Seizure risk due to acidic oil.

Solution: Oil analysis confirmed acidity. Flushed system, replaced oil and filter drier.

Result: Saved client AED 45,000 by preventing compressor burnout.

The Technical Log Report

Compliance is key. We provide detailed digital reports including suction/discharge pressures, oil levels, and amp draws for every site visit.

Parameter Logging

Documented pressures, temperatures, and voltages.

Instant PDF Delivery

Sent to Facility Managers instantly via WhatsApp/Email.

Job Card #8821

Generated on 12 Oct 2024

Engineer Notes:

Oil acidity high. Filter drier replaced. System stable.

Lifecycle Management & Asset Protection

Air Cooled Lifespan

Typical lifespan: 15-20 years. Regular coil washing prevents high head pressure, extending compressor life.

Water Cooled Plants

Typical lifespan: 20-30 years. Requires strict water treatment and tube brushing to prevent condenser fouling.

PPM Importance

Quarterly PPMs catch oil acidity and vibration issues early, preventing AED 50k+ compressor seizures.

UNITECH Chiller Specialists

Industrial HVAC Engineers in Dubai • Open 24 Hours

Ibrahim Al Mansoori

Local Guide • 2 days ago

We manage a mall in Barsha. UNITECH handles the Rooftop Chiller Maintenance. They performed chemical foam washing on the condenser coils and replaced the fan motors. Head pressure dropped significantly.

Thank you Mr. Ibrahim. Clean coils are essential for preventing High Pressure Trips in summer.

James Wilson

Local Guide • 3 days ago

Our tower had a compressor burnout. Their engineer diagnosed the electrical failure and replaced the Bitzer Screw Compressor within 24 hours. Very professional lifting and commissioning.

Sarah Jenkins

Local Guide • 1 week ago

The Cooling Towers were full of scale. They did a complete descaling and replaced the fill packs. The approach temperature is now perfect. Best industrial HVAC team.

Ahmed Bin Sultan

Local Guide • 2 weeks ago

The primary Chilled Water Pump was leaking in the plant room. They replaced the mechanical seal and aligned the coupling. No more floods.

Glad we could help, Ahmed. Mechanical seal integrity is a priority for us.

Robert D'Souza

Local Guide • 1 month ago

Our chiller lost all gas. They traced the leak to a vibration crack, brazed it, pressure tested with Nitrogen, and refilled R134a. System is holding pressure perfectly.

What Our Clients Say

"UNITECH saved our chiller during summer. The condenser tube brushing reduced our approach temperature by 3 degrees. Highly professional team."

Chief Engineer

Hotel Operations, Palm Jumeirah

"We had a compressor burnout on a Friday night. They arranged the crane and replacement compressor within 24 hours. Minimal downtime."

Facility Director

Mall Management, Mirdif

"Their vibration analysis predicted a bearing failure on our main pump. We replaced it during planned shutdown instead of an emergency crash."

Mr. Thomas

Industrial Manager, Jebel Ali

Frequently Asked Questions

Do you serve commercial buildings?

Yes, we specialize in Rooftop Package Units for malls, offices, and warehouses.

Is your work guaranteed?

Yes, we provide a 1-month warranty on service and up to 1-year warranty on replaced compressors.

How quickly can you arrive?

For emergencies in Dubai, our target arrival time is under 90 minutes.

Why is chemical cleaning necessary?

Water alone cannot remove the salt and dust cemented onto the aluminum fins. Chemical foam lifts this grime to restore heat exchange efficiency.